Rethink Metal Part Design And Produce Products, Components And Tools With Reduced Weight, Increased Functionalities And Simplified Assemblies.

Overview

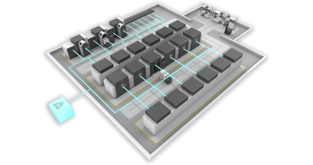

The ever-changing world of 3D printing has arrived at the fifth wave: 3D Production and it’s about to disrupt and revolutionize manufacturing as never before.

Many global brands like Airbus and Thales are turning to this cutting-edge technology because it delivers products what were once unmakeable – enabling radical designs and offering overwhelming benefits.

Manufacturers have made dramatic cost savings, accelerated time-to-market and discovered new levels of efficiency.

Know about these compelling benefits of Metal Additive Manufacturing:

- Reduce number of components from 20 to 1

- Reduce part weight by up to 50%

- Improve part performance

Metal Parts and Materials

Titanium

Titanium Alloy With High Strength, Low Weight And Excellent Biocompatibility For Technical And Medical Applications. Similar To Laserform Ti Gr23 (A), But With Higher Strength.

High strength, low weight, excellent biocompatibility

High strength, low weight, excellent biocompatibility – lower Oxygen than Gr5

Light weight, biocompatible, extreme temperature and corrosion resistance

Stainless Steel

Good for complex metal 3d printed parts with excellent strength, high ductility, wear and corrosion resistance. Stainless steel parts can be easily welded, CNC machined, spark eroded and polished – integrating conventional manufacturing processes with metal AM. Stainless steel parts produced with DMP/PBF/DMLS/SLM are typically used for machine components, food-safe applications, medical devices and surgical instruments. Steel alloys are often used for spare part production. Select alloys with thoroughly developed and tested print parameters.

Able to be sterilized and highly corrosion resistant.

Excellent corrosion resistance, high strength with good toughness

Excellent corrosion resistance, high strength with good toughness

Able to be sterilized and highly corrosion resistant.

Maraging Steel

Use genuine tool steel (1.2709) for the direct production of tools, molds and high-performance parts that require high strength and hardness. Metal 3D printing enables direct inclusion of conformal cooling channels for improved head management in injection molding tools, enabling shorter cycle times and longer tool lifetime. Shows good weldability and machinability for post-processing and integration of additive with conventional technologies for a reduced total cost. Available with thoroughly developed and tested print parameters.

Excellent hardness and strength, good wear resistance.

Genuine tool steel (1.2709), high strength and hardness

Cobalt Chromium Alloy

For Industrial and Dental use- Used for highly corrosion-and wear resistant industrial parts that require high-temperature resistance. Can be used for reducing weight, improving fluid flow and consolidating parts for turbine and engine components, design and watchmaking products, parts with thin walls or fine features and mechanical components needing wear and corrosion resistance. Available with thoroughly developed and tested print parameters.

Highly corrosion, wear and heat resistant. Bio-compatible.

Highly corrosion and wear resistant, suitable for biomedical

Aluminum Alloy

The potential for weight reduction through part design is a big benefit In metal 3D printing, Aluminum alloys are often used for light-weight, high strength applications in automotive, aerospace & machinery. Innovative applications such as mold design and specific heat exchanger applications make use of the high thermal conductivity of specific aluminum alloys. Available with thoroughly developed and tested print parameters.

Light weight, good mechanical properties and improved thermal conductivity

Good mechanical properties and good thermal conductivity

Metal powder for light weight parts with good thermal properties

Nickel Super Alloy

Used for complex parts, often including improved fluid flow in high-temperature and high-strength applications. Metal 3d printing achieves material properties that exceed those of different casting processes. Ideal for gas turbine parts (IGT), exhaust systems, machinery and process industry parts. Available with thoroughly developed and tested print parameters.

Excellent corrosion resistance, high strength and heat resistance

Excellent corrosion resistance, high strength and heat resistance

Oxidation, corrosion and extremely high-temperature resistant