Overview

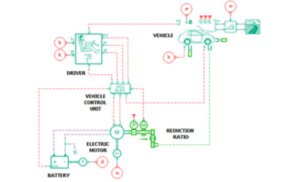

Automotive and Transportation industry has seen phenomenal growth in the last few decades. As the buyers are more concerned with safety and advanced features of the vehicles, the manufacturers are more focused on saving costs and increasing productivity without compromising on the quality and safety. Interestingly, simulation and PLM software tools allow automotive manufacturers and their suppliers to earn handsome returns on their invested rupees with the proper use of solutions. Product Lifecycle Management software eases manufacturers task as it streamlines the whole manufacturing process from concept to recycle. Moreover, productivity enhancement tools such as plant and process simulation, planning and scheduling software as well as quality management solutions allow automotive manufacturers to enhance their profitability. Most automobiles are not only mechanical structures with the best of the aerodynamic shapes, but also the best of the integrated computer systems and high-frequency antennas to provide the users with the superior user experience. The roll-out of electric vehicle technology has further changed the dynamics of the automotive industry altogether and has paved a new way of mobility for the near future.

SOLUTIONS

Our Unique Offerings

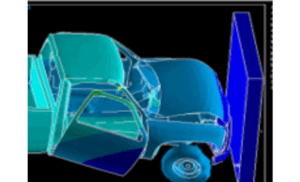

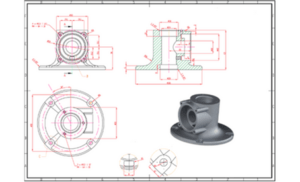

CAE, Component Design, Tool Design, CAM Design

Automotive industry needs different solutions for their mechanical, electrical and software systems design for modern vehicles. Plastic Injection Mould and sheet metal die designs integrated with the product design ensures quick turn-around time. Automotive industry uses our solutions to deliver innovative technologies and solutions across a global delivery footprint without compromising any of the quality, cost and timing requirements of their customers.

Data and Lifecycle Management

Automotive & Transportation industry has to face ever growing challanges to be cost-competitive yet efficient. A lifecycle approach to process and data management is critical to meet these challenges. Our solutions address how you manage change, execute work processes, drive quality, and connect to external suppliers and customers. Our lifecycle management approach to centralizing technical information and keeping it up to date and accessible, means knowledge workers can be more efficient and achieve higher levels of performance.

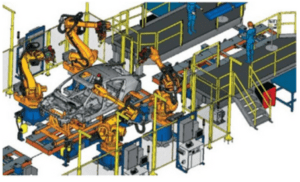

Plant Design and Simulation

Using factory layouting tools, plants and processes can be simulated to get optimum throughput. Balanced lines for a combination of product mix ensures that the investments are in control. With Siemens controllers for manufacturing automation, the lifecycle tools can be integrated to virtually commission machines to ensure quick turnaround.

Services Offerings

Automotive

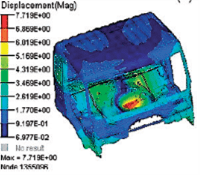

Safety

NVH

Durability

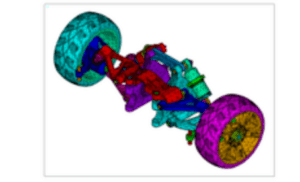

Vehicle Dynamics

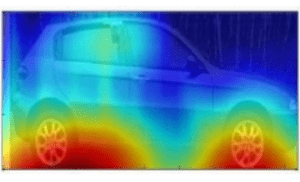

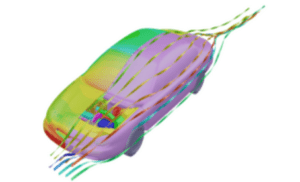

Aero and HVAC

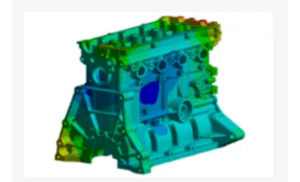

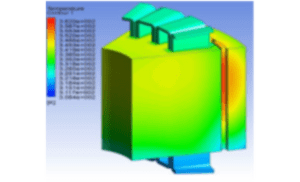

Underhood and Powertrain Cooling

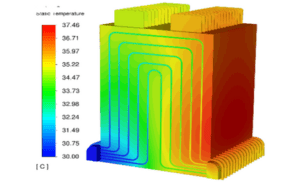

EV- Motor Thermal

Battery Thermal

1D- Performance Simulation

CAD Modeling