Overview

Manufacturers around the world are facing a multitude of challenges and are looking for far more complex equipment customized to their specific needs with higher reliability and reduced delivery time. Industrial Machinery and Equipment (IM&E) manufacturers must adopt latest technologies to sustain in this fast-paced hypercompetitive world. As success requires tightly integrated processes paired with the ability to continuously assess and improve product designs, manufacturing efficiency, product quality, and service. Siemens Product Lifecycle Management (PLM) helps manufacturers unify the global design, engineering, and manufacturing teams so they are able to work on the same requirements, models and manufacturing process plans while having the flexibility to meet local configuration needs. Its PLM solutions help enterprises to improve productivity, reliability, and profitability for heavy equipment. In an increasingly competitive market, companies must ensure innovation and manage complexity. Siemens PLM Software can help you build the right product, and build the product right.

SOLUTIONS

Our Unique Offerings

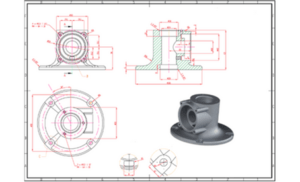

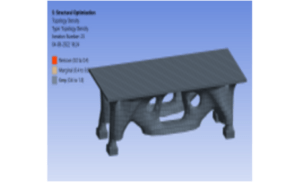

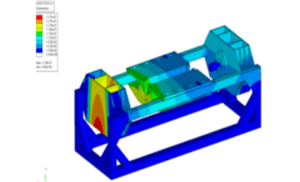

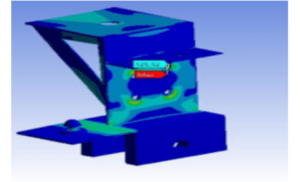

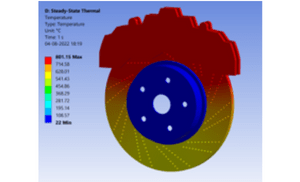

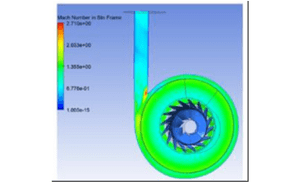

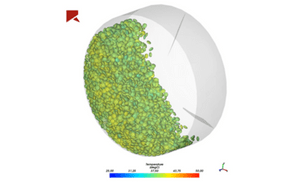

Design of Machines

Small and large machine can have several parts made in plastic, metals, and composites. Design of machines now needs a lot many tools than in the older days. Machine makers now need to have tools that help them design their machines optimally, test them virtually for their performance, follow regulatory compliances and create user manuals for its maintenance and service. 3D Engineering brings to the industrial machine makers a host of technologies that help machine makers do all of this and more.

Data and Lifecycle Management

A machine can have thousands of parts with several subassemblies. Machines now have mechanical as well as electronics and even computers embedded into them. It is quite obvious that the design of machines is no longer a single person’s job. It is now done by a team of members who need to collaborate to make sure that they are all talking the same design language. PDM (Product Data Management) and PLM (Product Lifecycle Management) tools help machine manufacturers design their machines more efficiently.

Virtual Commissioning

Machines have a lot of automation these days and can have PLC controllers within them to help them operate in a sequence they are meant to along with the safety and compliance protocols the machine has to follow on the shop floor. Siemens Factory Automation division has been supplying automation and controls equipment to machine makers for ages. Now machine makers can virtually commission their machines before they are commissioned on the shop floor. 3D Engineering helps bridge the gap between these technologies for its customers.